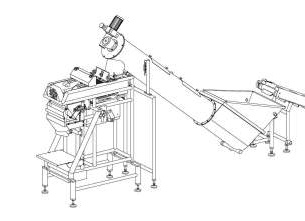

Dosed goods transported from hopper by three vibrating trays into the weighing pocket. The troughs variable amplitude system ensures efficient flow of goods into the weighing pocket.

Linear automatic weighing equipment may be applied separately or included into a packaging line for potatoes, onions, small goods such as seeds, dried fruits, baby onions etc.

The operator the bag slides on neck of dump, by means of a foot switch empties weighed dose. The desired dose can be entered into the memory of computer. The accuracy of the final walue is derived from the size of individual components dosed and size of the total weight. Precision of the weighing system is equivalent to ∓1g.

Equipment is possible to place on the platform above the hopper of automatic packaging machines, consisting of the individual bags from the roll of packaging material.

In this case, the dose a small pieces of goods as seeds, dry fruits, baby onions etc.

Technical parametres

| Power supply | 3x230/400V/50Hz |

|---|---|

| Supply | 0,5 kW |

| Weight range | 0,1 – 10 kg |

| Compressed air consuption | 140 l/min |

| Potential capacity for 1 kg | 10 - 15 bags/min. |

| Maximal noise | 70 dB |

| Precision of weighing system | ∓1g |